Marc Vandemoortele

De Smet Engineers Contractors

Marc.vandemoortele.ext@dsengineers.com

Specific aspects of sugar boiling and batch pan automation

Supersaturation and secondary nucleation are key concepts in the crystallisation process of sugar solutions.

Supersaturation is the driving force for crystal nucleation and growth. It occurs when a solution contains more dissolved material than it can theoretically hold at a given temperature and pressure. Supersaturation is crucial for initiating crystallisation.

Secondary nucleation involves the formation of new crystal nuclei in the presence of existing crystals. It can be triggered by factors such as mechanical agitation, impurities, or the presence of seed crystals. Management of the secondary nucleation is essential to control the size and number of crystals in the final product.

Although supersaturation is the driving force for crystal growth, exceeding supersaturation leads to unwanted nucleation resulting in the production of fines and the formation of twins and conglomerates. When a larger number of fines or conglomerates are present in the output sugar, this leads to increased recirculation in the crystallisation, which results in a poor crystal recovery yield and higher steam consumption. As supersaturation is not a measurable parameter with one single device, it must be determined by evaluating the conditions of brix, purity and temperature of the mother liquor surrounding the crystals under development. Concerning the crystallisation step, the batch pan automation shall use the brix – level curve to monitor and properly steer the supersaturation. The brix-level curve in the program logic should not be fixed but should be continuously recalculated using a set of specific parameters for each step of the boiling.

At the start of the crystallisation step, the program saves the “brix starting point” and recalculates a curve to achieve the target endpoint of the crystallisation step. This endpoint is fixed by the pan level and brix parameters.

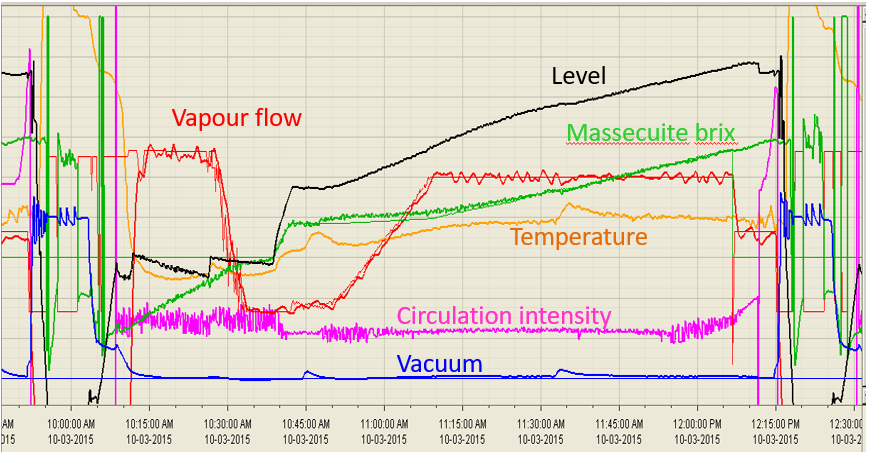

At the beginning of the boiling, the crystal surface is limited, impacting the crystal mass growth negatively. Heat transfer coefficient is high due to low crystal content and low viscosity. Consequently, the evaporation rate inside the pan must be adjusted to match the crystal mass growth with the supersaturation. This is usually done by adjusting the vapour pressure to the pan. In the DSEC pan automation system, the vapour flow is controlled by means of a venturi flowmeter and a control valve enabling more accurate and specific vapour regulation. In DSEC’s control logic, a steam curve is implemented to supply the right amount of steam at each step of the boiling process. This curve allows better control, especially during seeding and the first stages of crystallisation.

Controlling both supersaturation and steam flow leads to a uniform and uninterrupted boiling process. This means that there is no need to use water or lighter syrups to wash and dissolve the false crystals. The absence of water addition also reduces the sugar colour by avoiding the “enclave inclusions” phenomenon. When water is added, small crystals and the outer layers of the big crystals are dissolved. Rounded crystals can be seen under a microscope. When the crystal surface is altered, local crystallisation rate can drastically increase during the subsequent regrowth of the crystal. Syrup inclusions occur, leading to an increase in the global colour of the sugar.

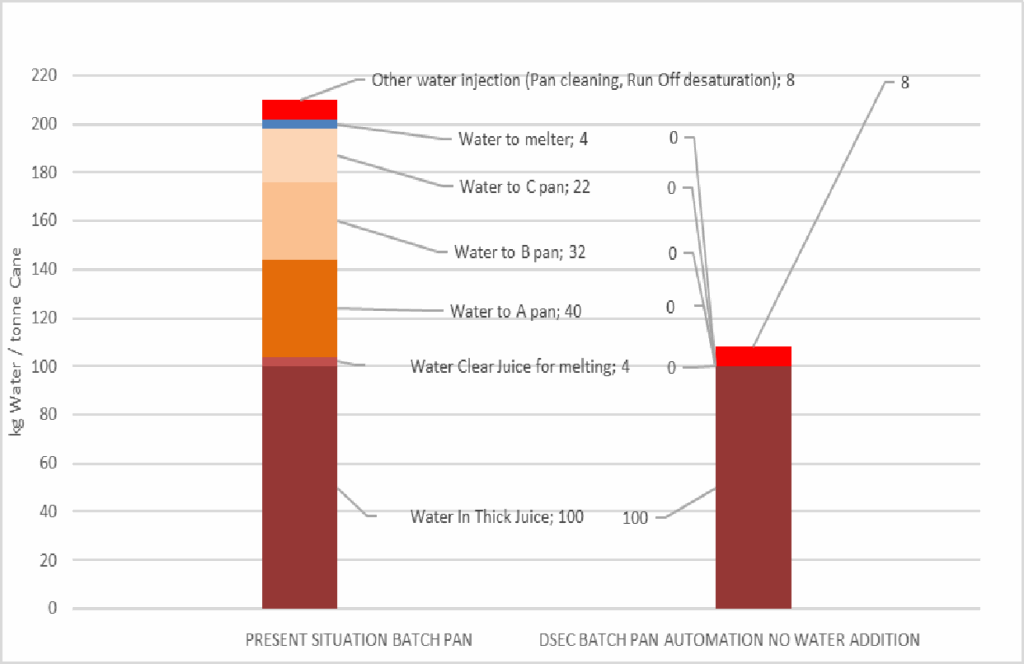

Figure 3 shows the various water injections in the batch pan:

- Water in thick juice.

- The water in the clear juice is used for melting. This can be reduced by melting with thick juice.

- The water added during boiling cycle A / B / C to correct the crystal quality (dissolving of fines). This is the water injections to avoid fines due to the automation.

- The other water injections such as pan cleaning water and molasses conditioning water. This can be optimized but not avoided.

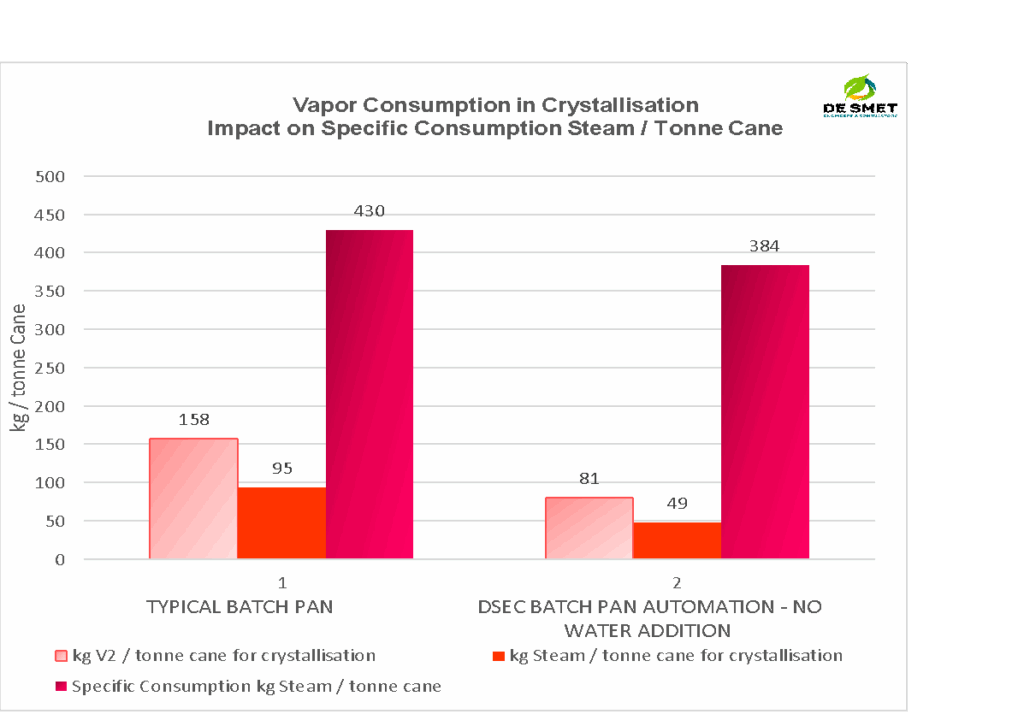

The combination of the batch pan automation without water additions and the use of syrup, instead of water or clear juice for the melters, did allow to reduce the plant steam consumption by 11% by dropping from 430 kg of steam per tonne of cane to 384 kg of steam per tonne of cane (Figure 4).

In terms of quality, the request was to produce refined sugar crystals with an MA of 0.85 mm and CV lower than 32. For the raw sugar, the target was to produce crystals with an MA of 1 mm and CV of 30. After automation of the refinery batch pans, the results with no water addition were achieved with an MA from 0.83 mm to 0.87 mm and CV lower than 30. The boiling cycle duration of the pan was reduced by 10%.

For the raw sugar pans, the results with no water addition were achieved with an MA of 0.95 mm to 1.05 mm and CV between 27 and 29. The colour of the raw sugar dropped from 1000 IU to 700 IU.